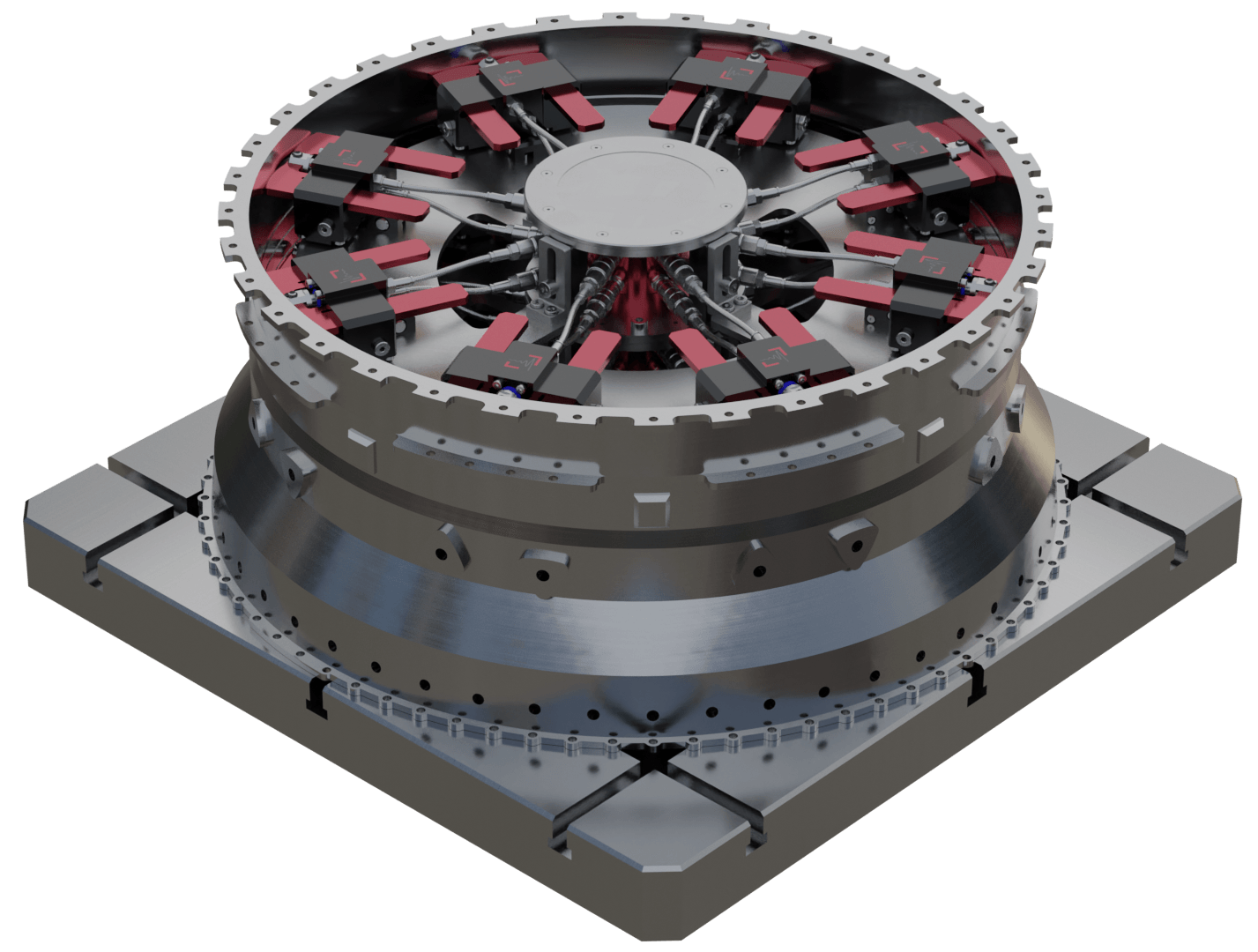

Modular clamping

for every workpiece

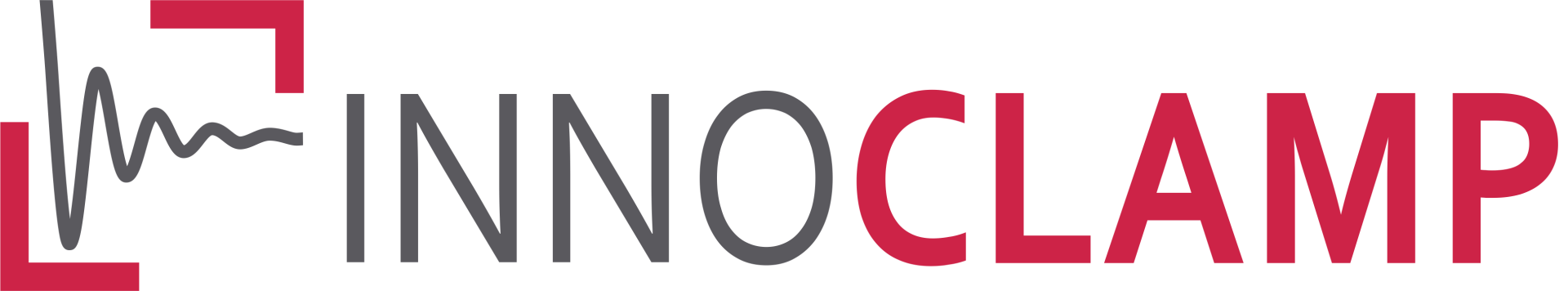

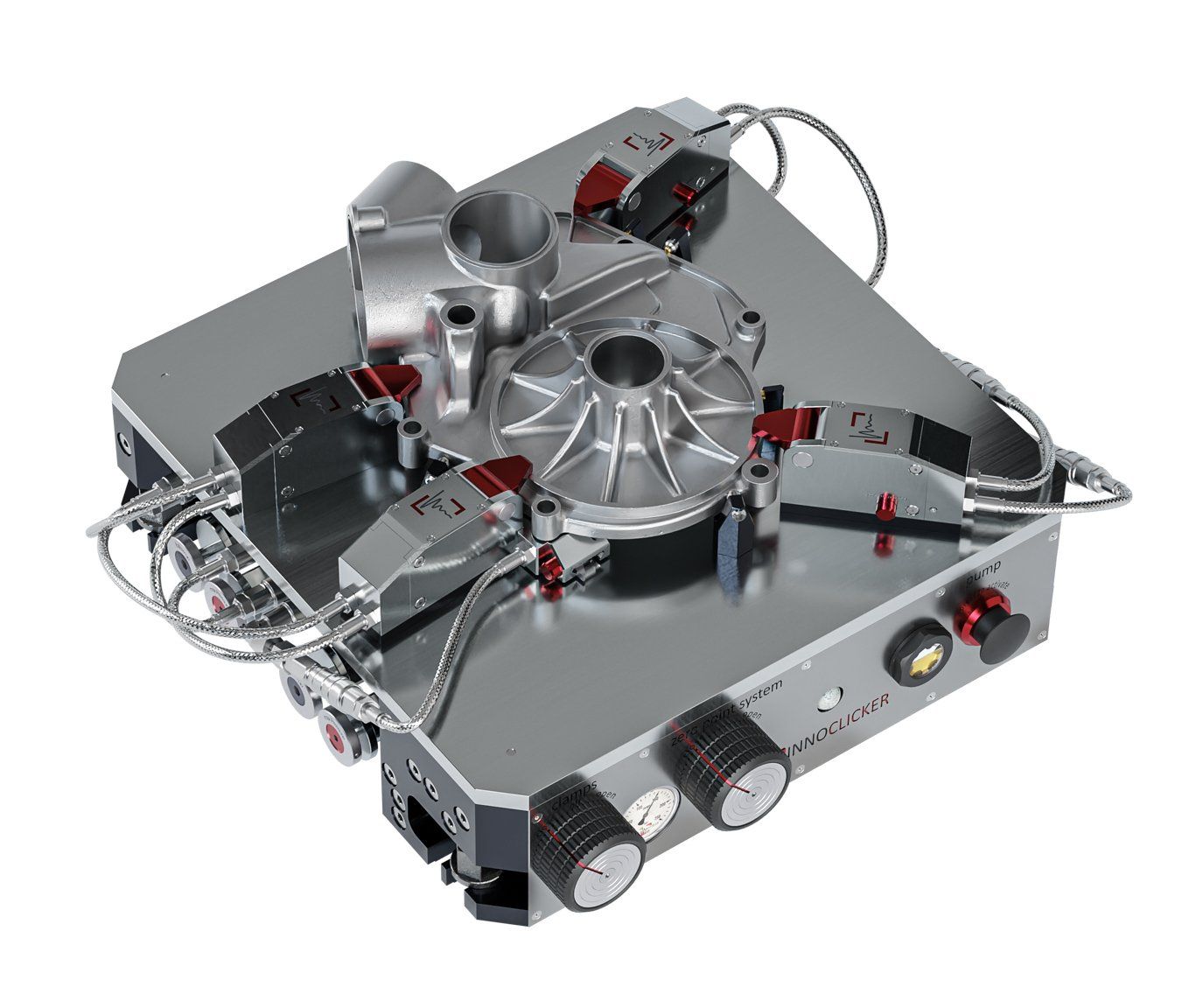

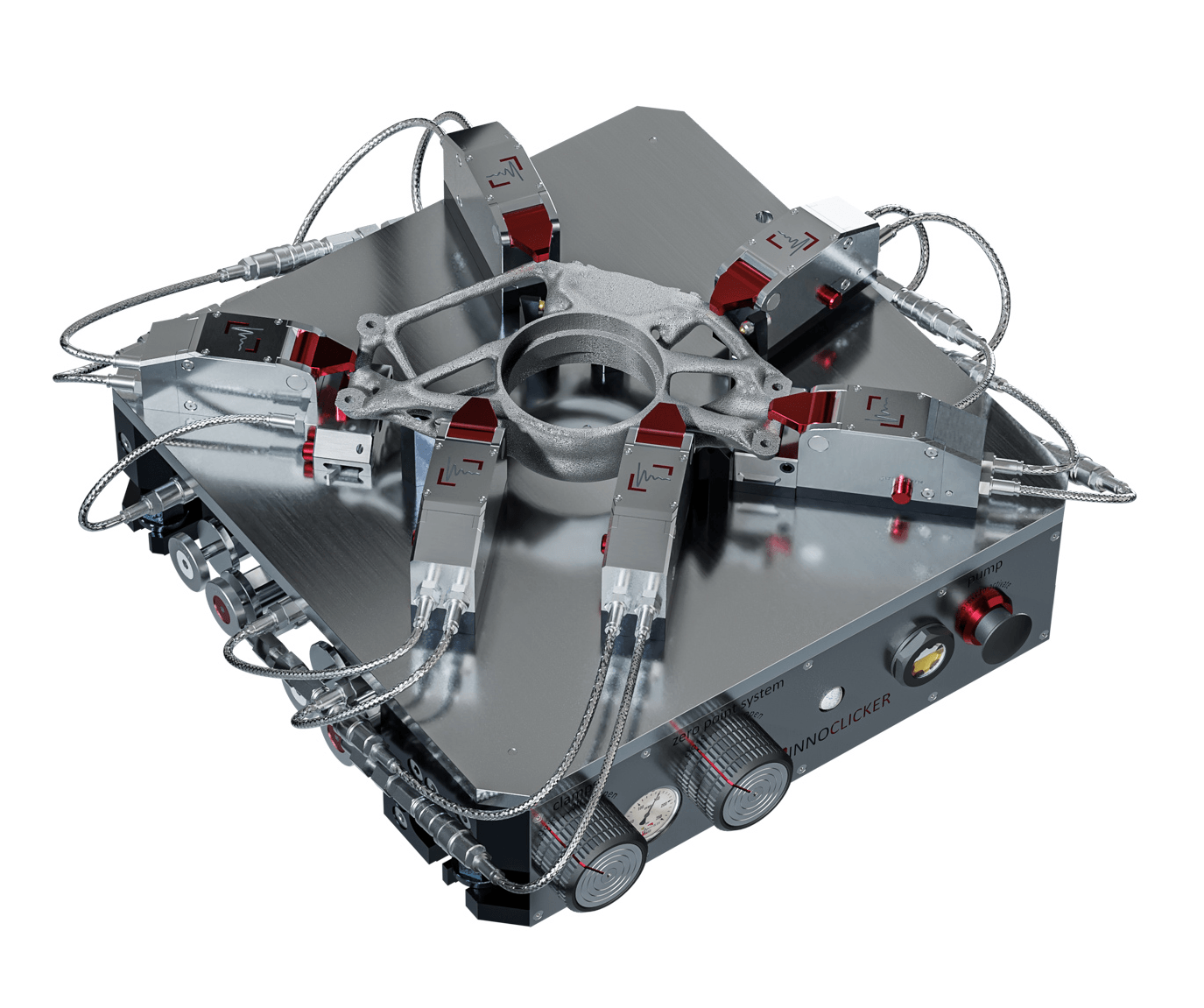

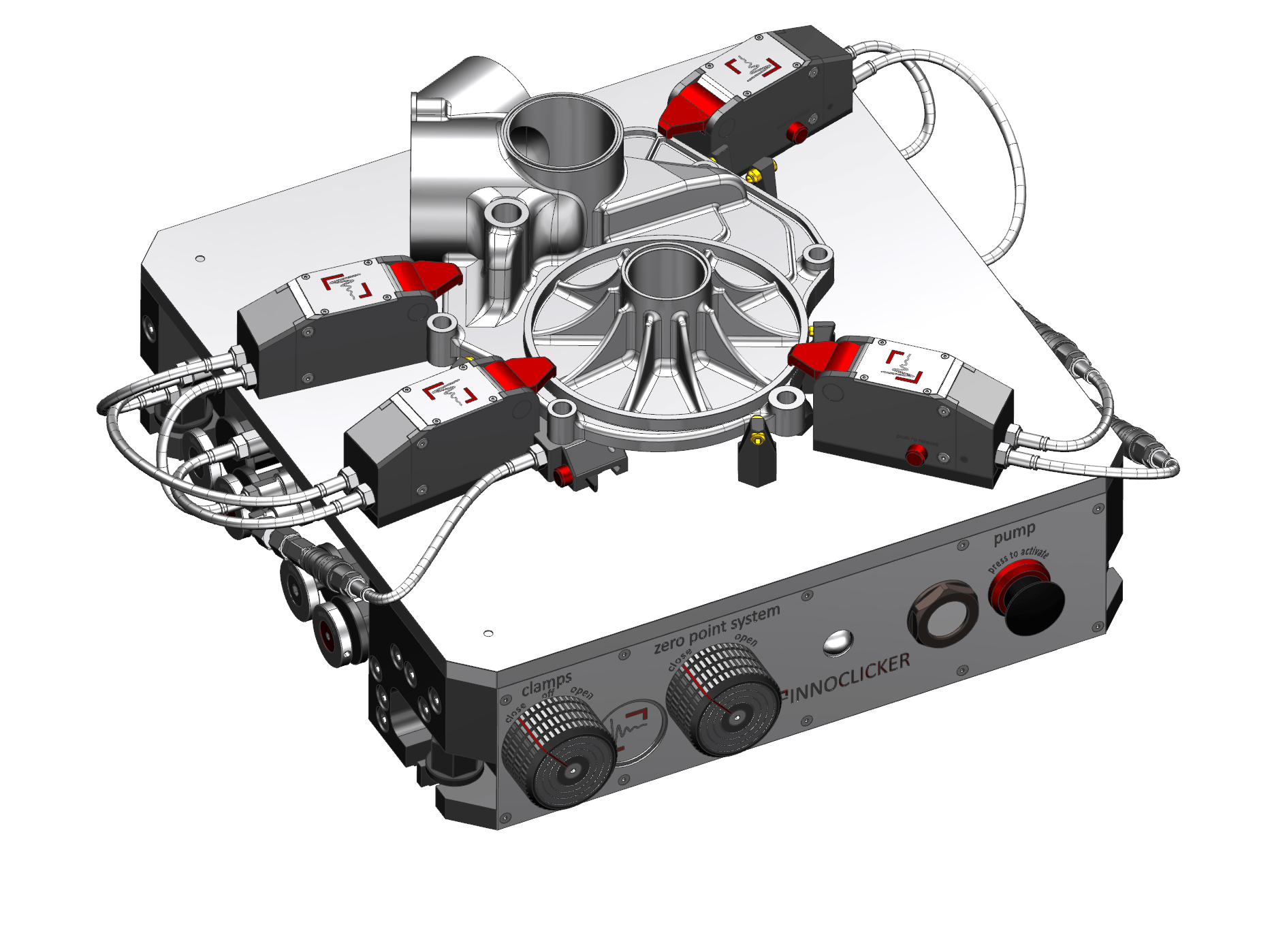

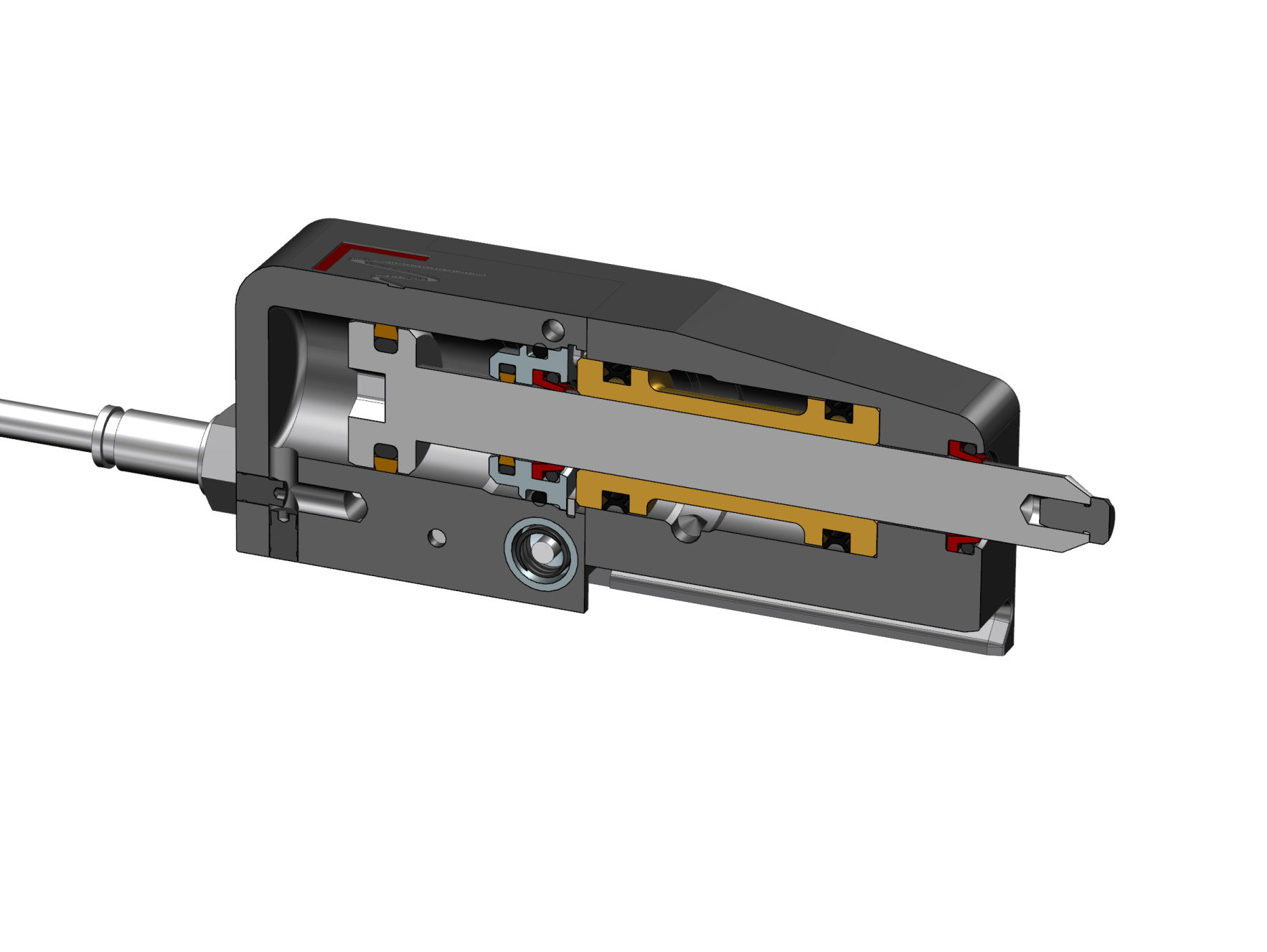

Clamp every workpiece in your production flexibly and fully automated with the INNOCLICKER

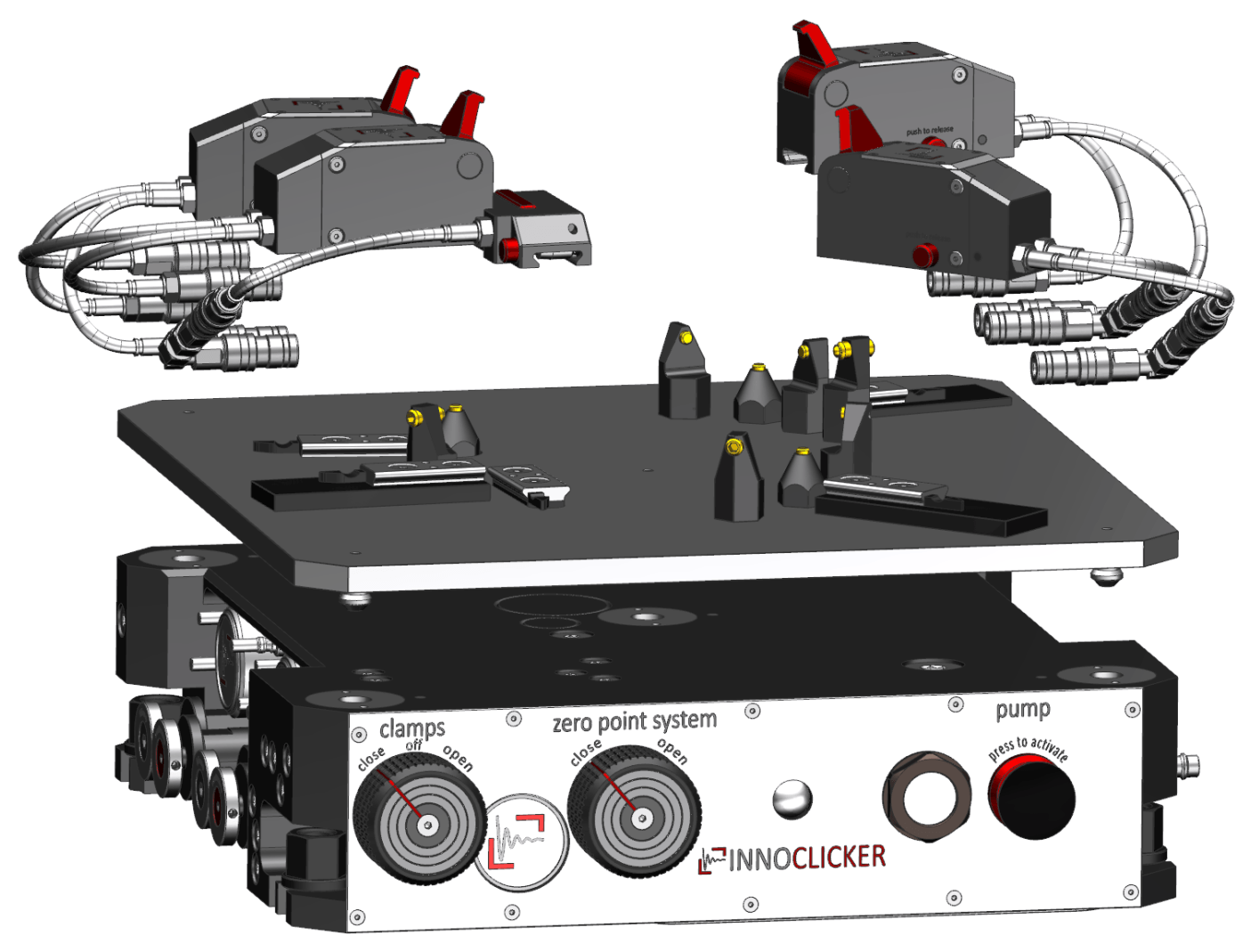

Flexibly suited for any workpiece

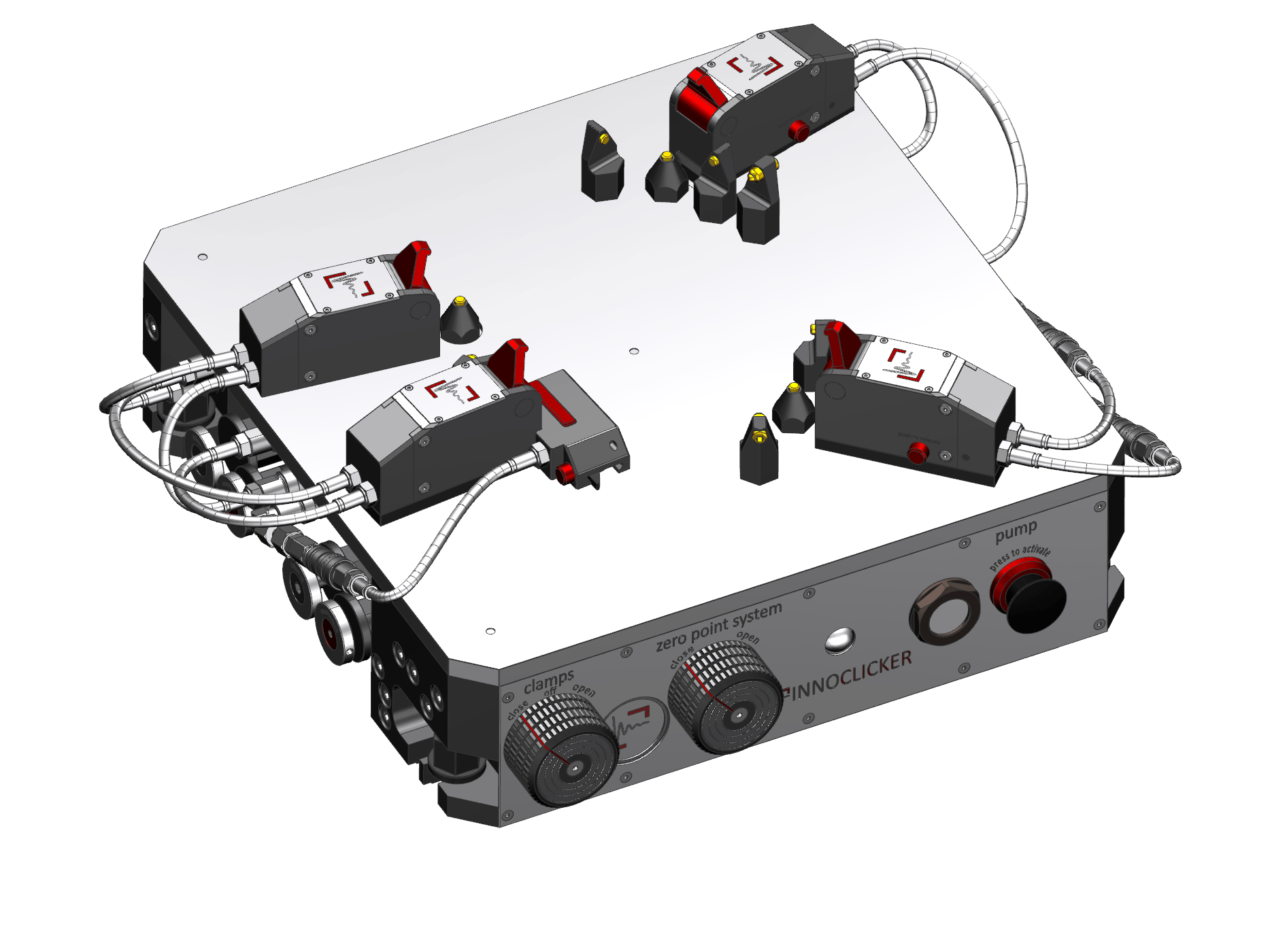

With our INNOCLICKER clamping system you clamp all workpieces of your production with only one system.

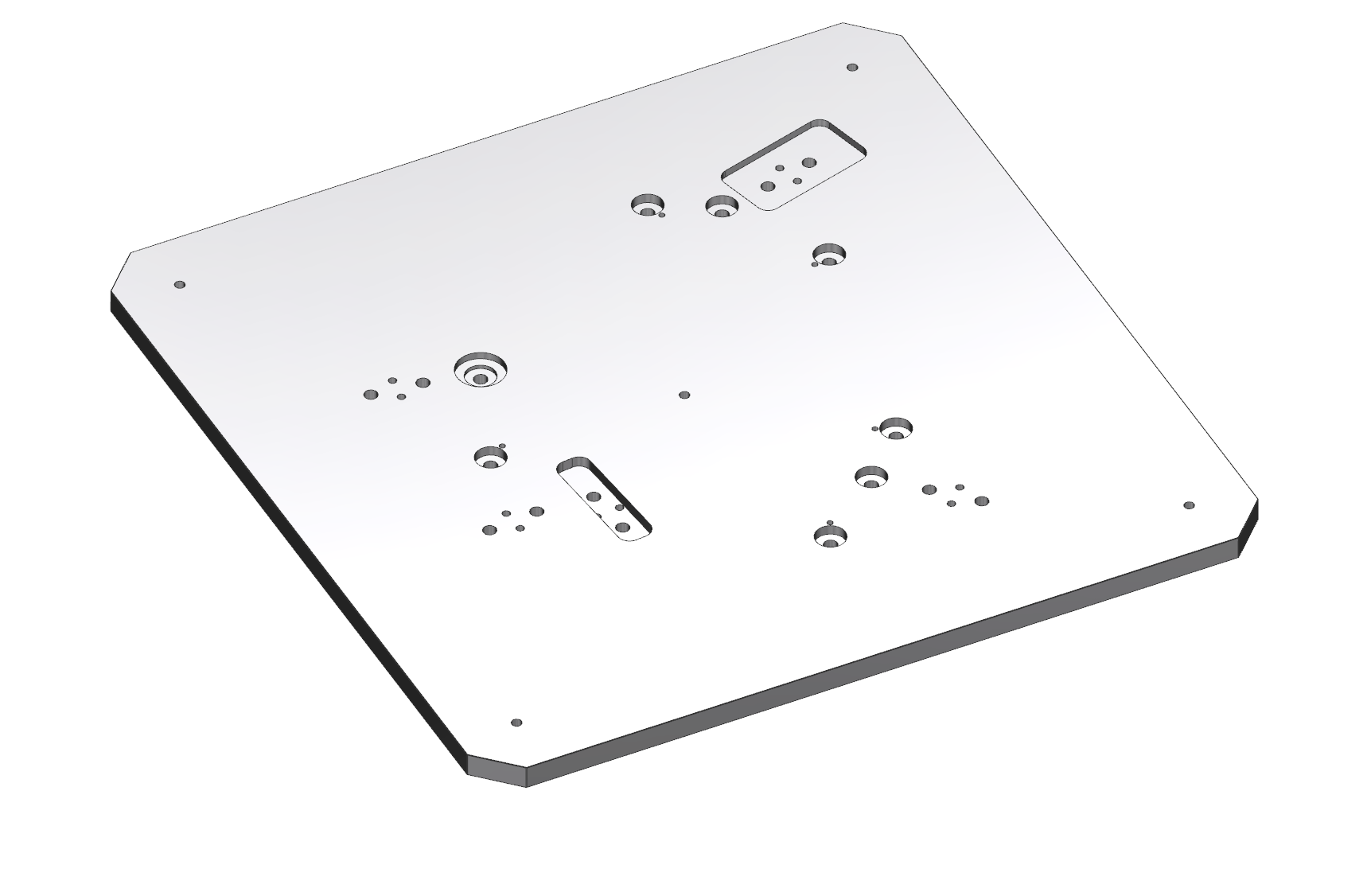

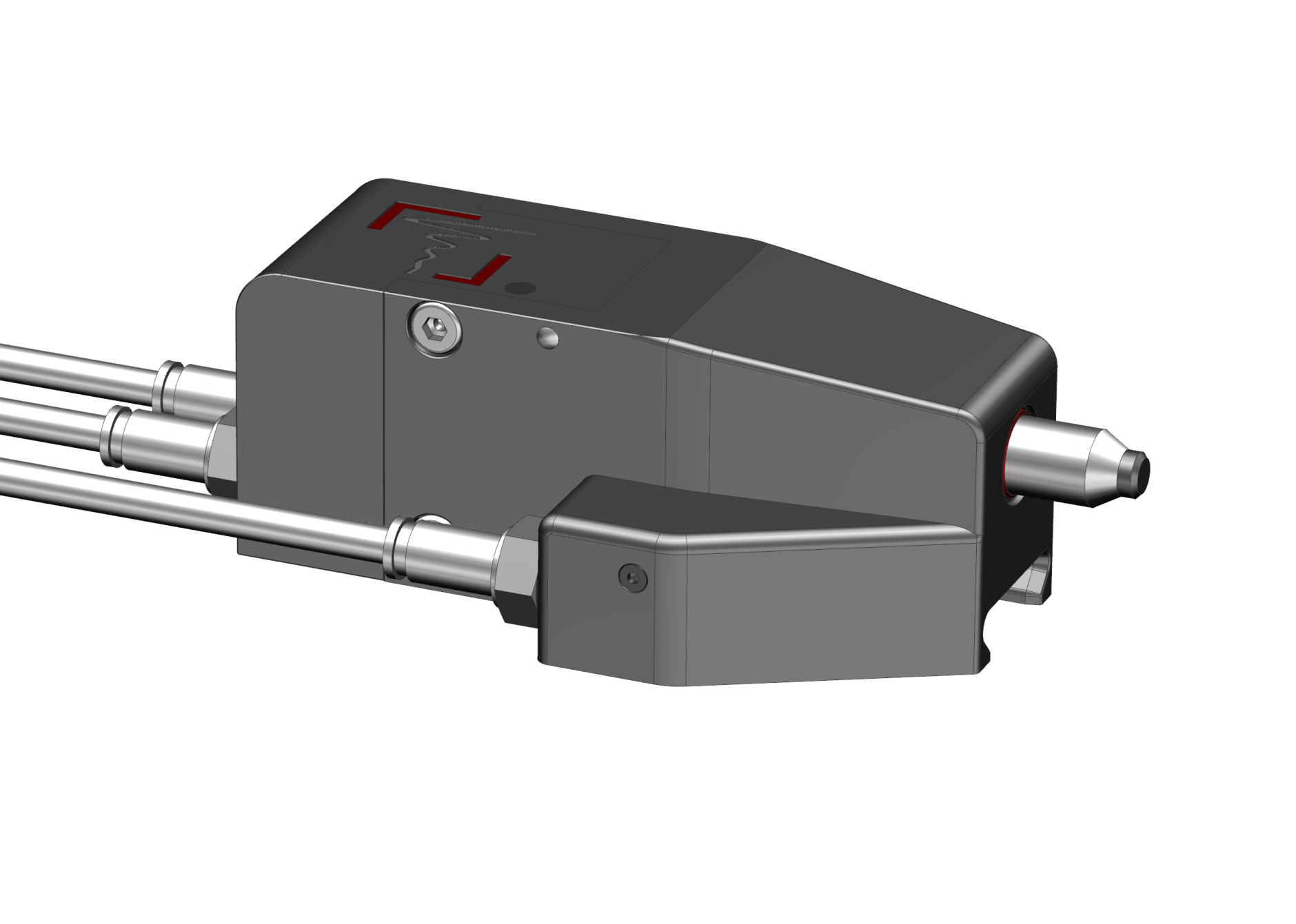

The modular design of the system enables you to be flexible and you can reuse all hydraulic components for other workpieces.

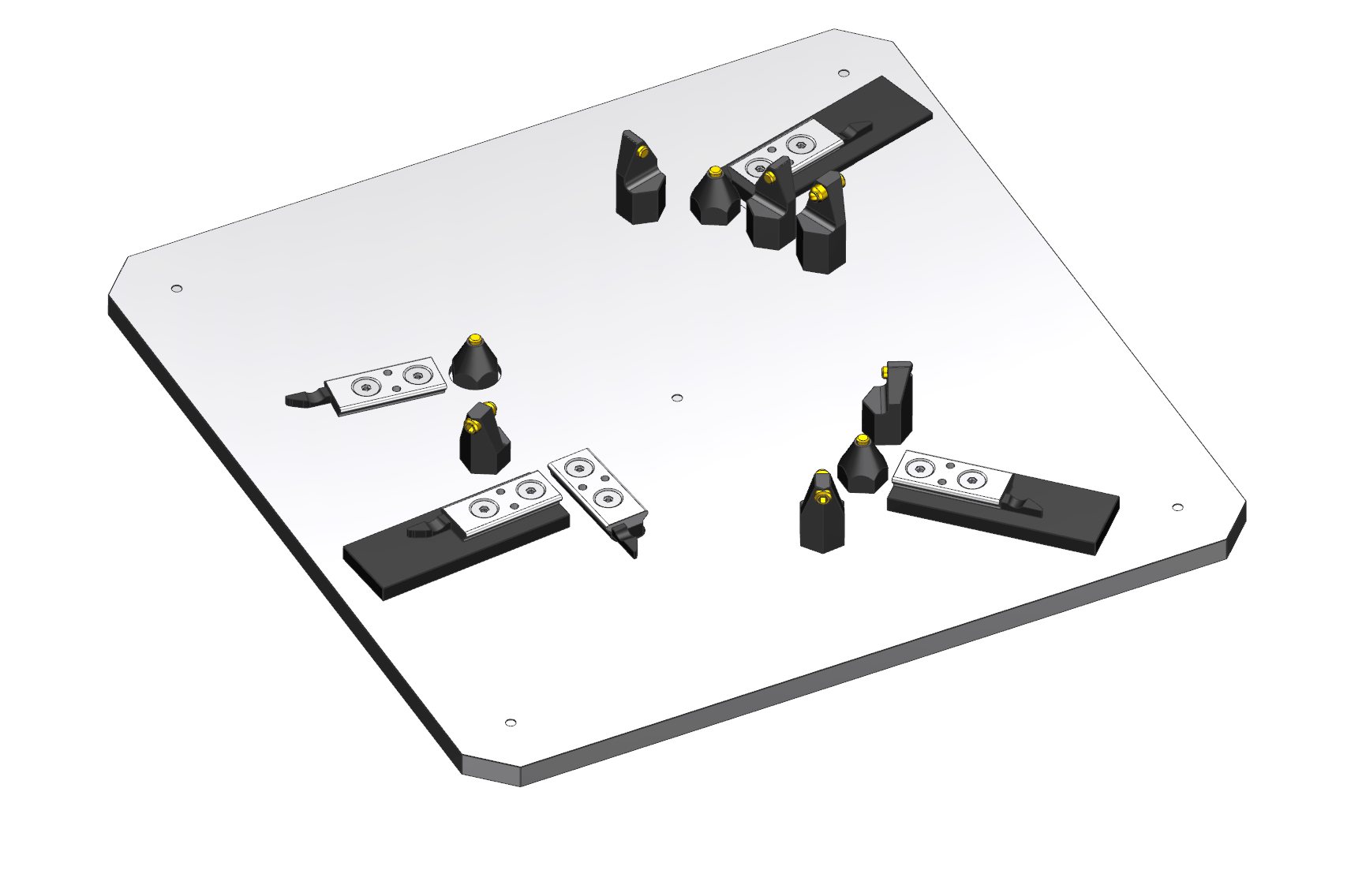

Modular design

Simple clamping plates

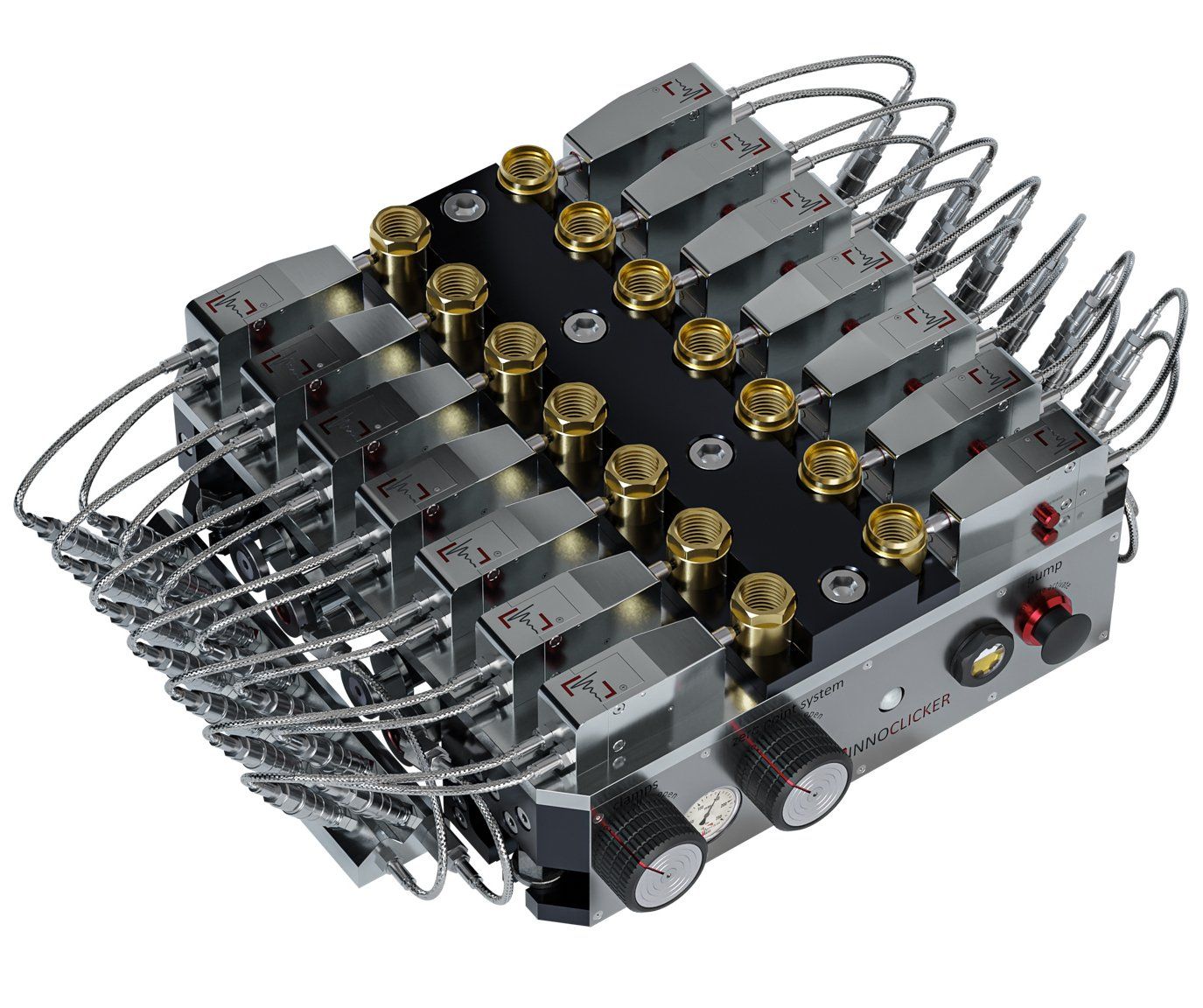

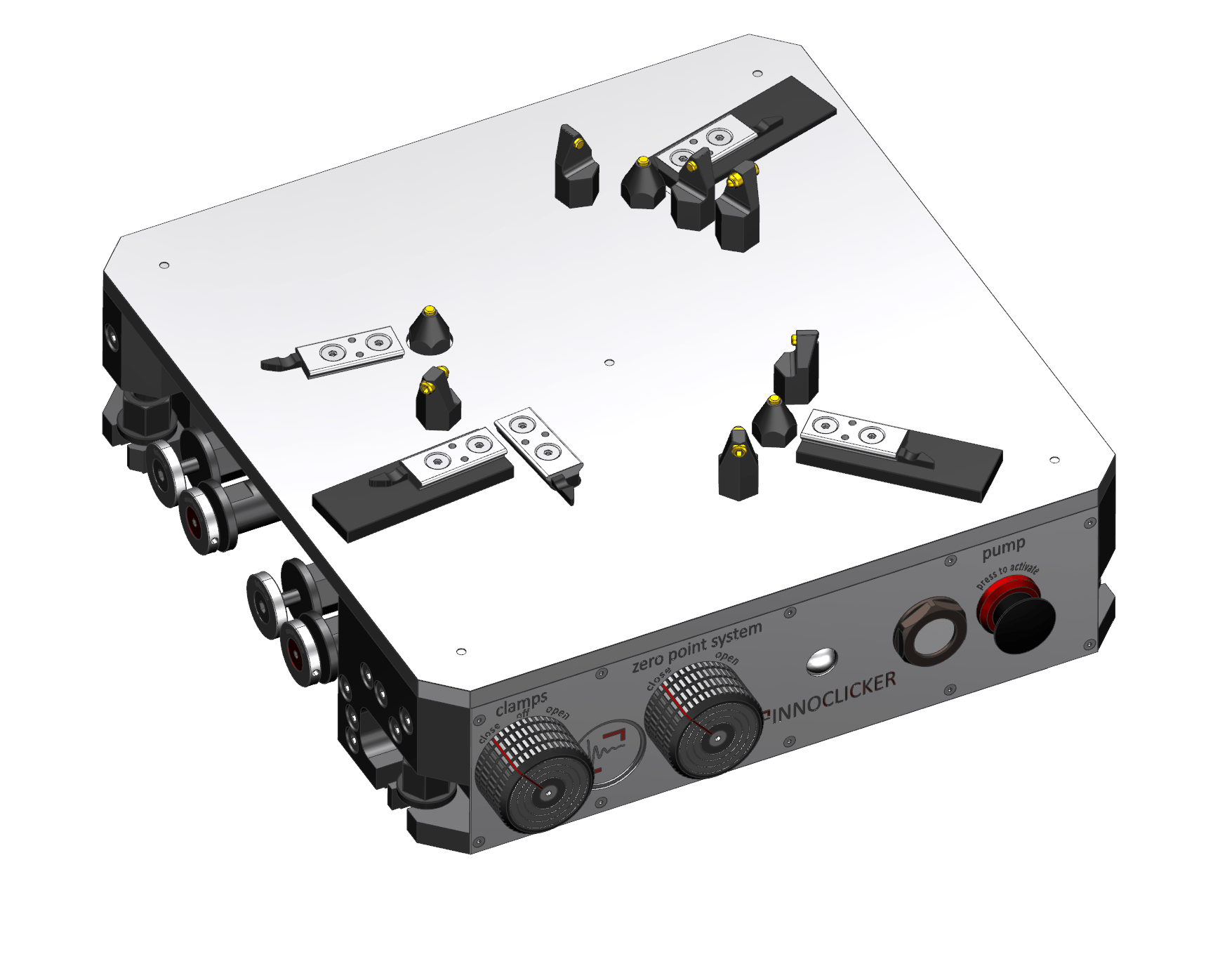

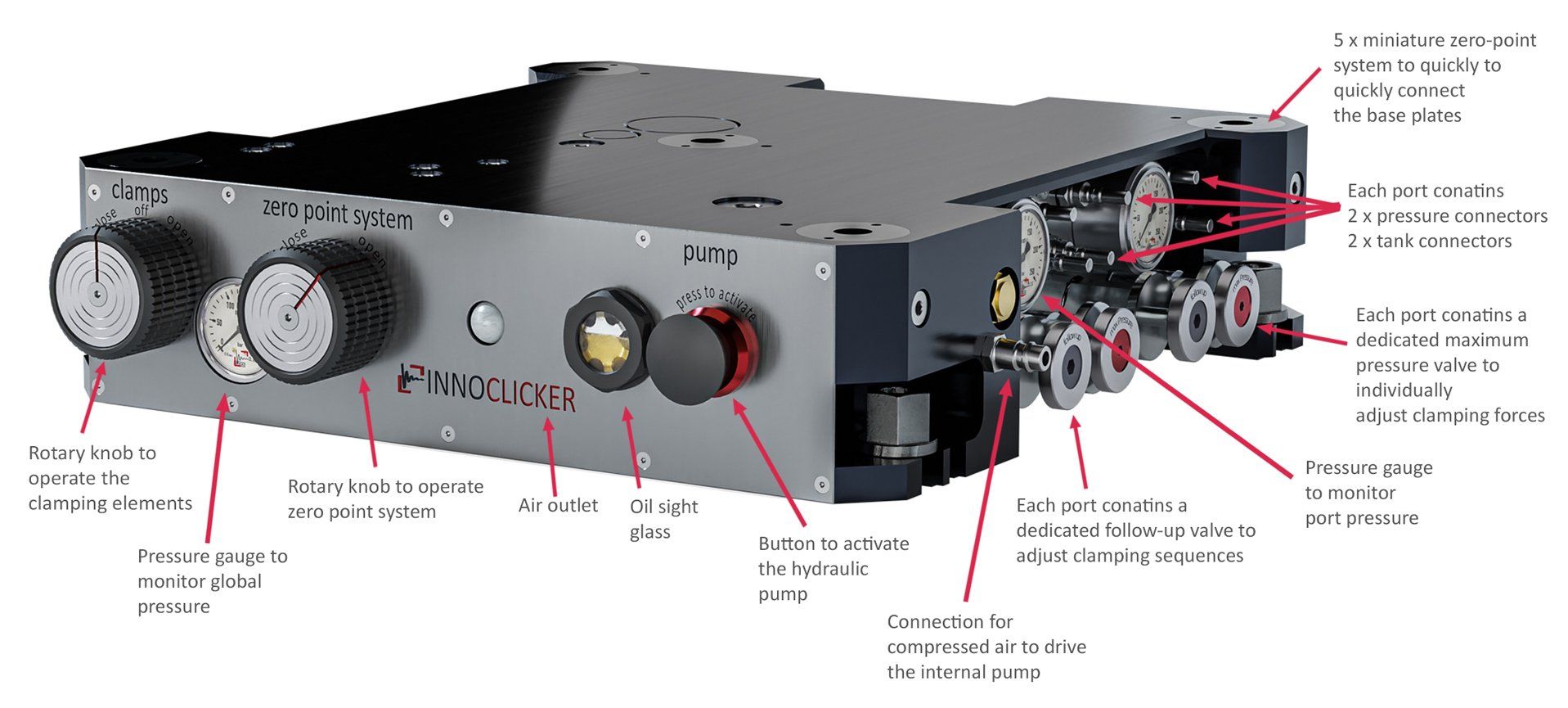

The supply station

The supply station has five zero-point chucks on its upper side to fix the clamping plate. There are several pressure modules on the sides on which the maximum pressure and clamping sequence for each clamping module can be set individually. The hydraulic pressure is generated by a built-in, pneumatically operated pump. An external hydraulic pressure supply is therefore not required for operation, just connect compressed air.

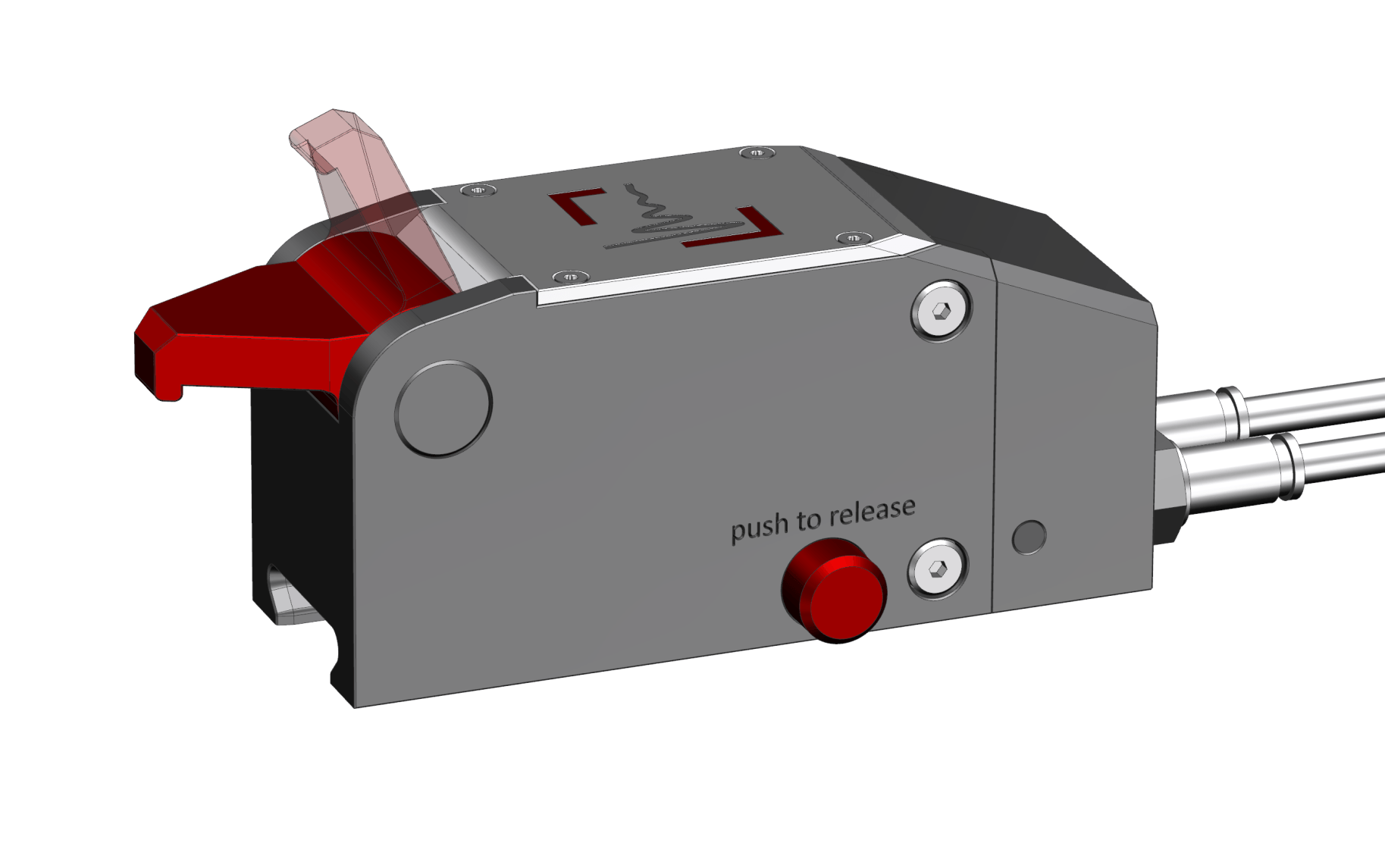

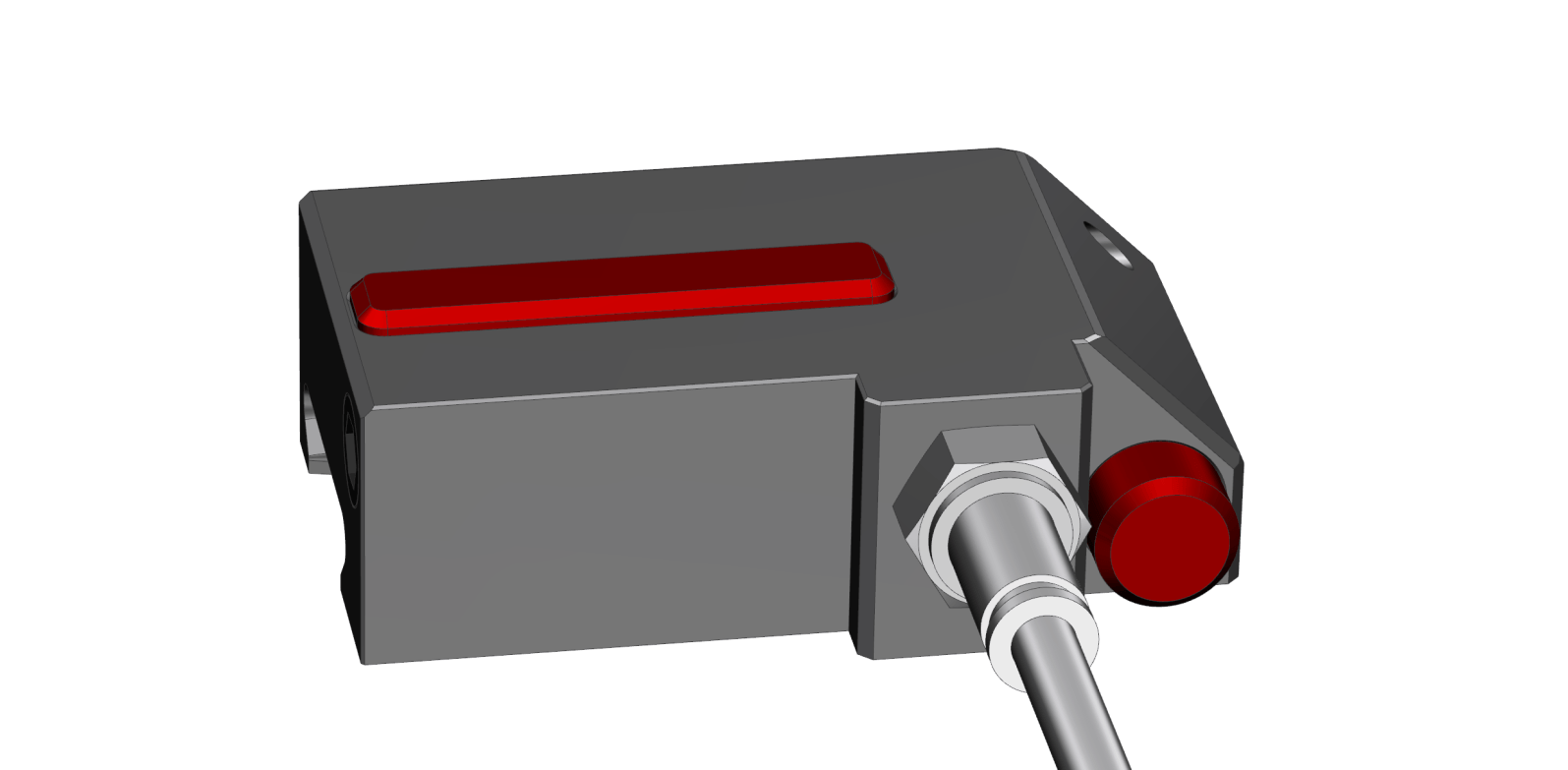

Innovative modules

Fastest delivery time

Our INNOCLICKER clamping system can be adapted very quickly to your new workpiece.

More efficient CNC machining processes

The powerful hydraulics and high vibration damping characteristics of the INNOCLICKER enable faster production.

Optimized for production

If necessary, you can simply replace the components yourself and always produce without interruption.